Hey!

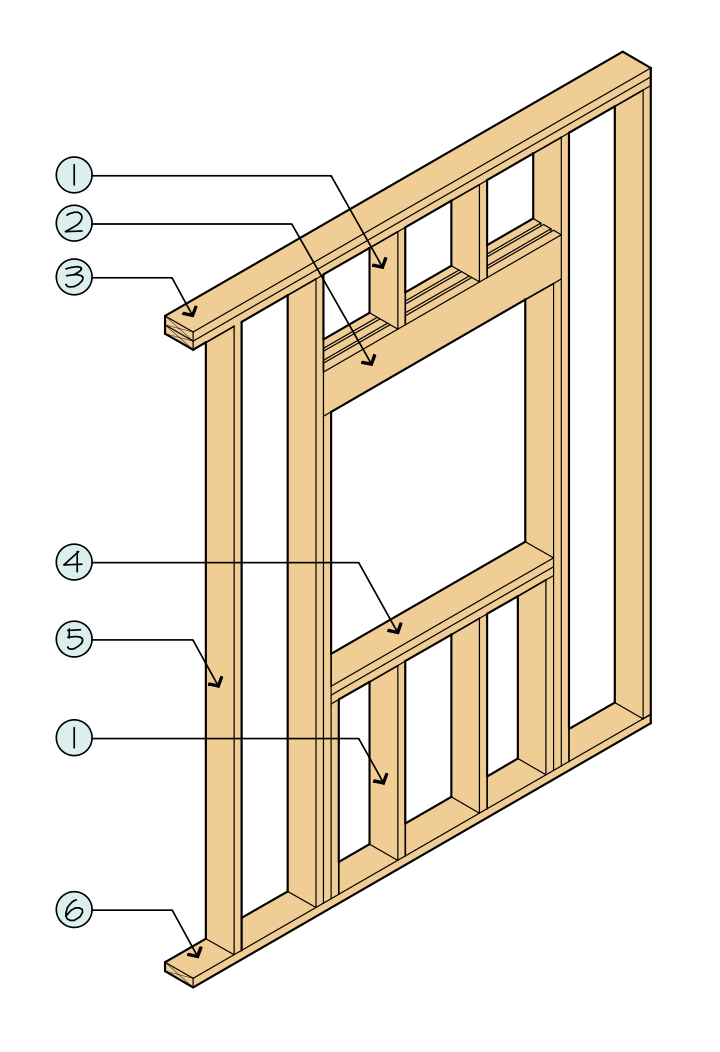

Currently doing drywall myself and I am using 6x6 cm squared timber around my outside walls.

The problem is they aren’t as stable as the other walls inside the house because of the 6x6 cm squared timbers that are about 30cm distance from each other.

I will screw my plasterboards on the squared timber and only one plasterboard, not two.

I have two pictures of what my construction looks like from far and one from close.

Maybe someone can give me advice before I install the plasterboard onto it.

The only problem I currently see is finding the subconstruction once I put the plasterboards back on. But other than that, if I find them can I install the cabinets safely?

In this thread: OP scaring the Americans because they think what they see in OP’s pictures is the extent of the wall.

If fact, OP is just building out from an existing wall that is behind the OSB in his pictures.

Grogon, ask a local carpenter. I don’t think Americans understand your German construction.

Sarry buddy but yor camment ain’t upda code. Gatta rip it out n stard agin

I’ll answer this one in German since this is my time to shine. Let me just say, the wall is perfectly fine, what we see is just another layer of OSB board for ease of installation on top of the actual wall behind it (which is well framed and insulated).

Dies ist ein sehr unterhaltsamer thread fuer mich, da ich beide Seiten verstehen kann.

Auf der Webseite von Wolf Haus ist die Installationsebene aus OSB zu sehen, die angegebene Punktlast ist 70kg pro Schraube. Wenn du sicherstellst, das deine Schrauben durch die Kanthoelzer in die OSB-Platte gehen, solltest du dich auf diese Angaben verlassen koennen, also eine Schraube haelt dann 70kg.

Deutschland hat selbstverstaendlich auch eine Norm fuer Kuechenmoebel, DIN 68930. Da bekommst du ein Gefuehl dafuer, wie schwer Kuechenschraenke werden koennen. Die Nachbarn in der Schweiz verwenden die Norm SN EN 14749, zum Vergleich. Es ist nicht ungewoehnlich, einen Schrank (wall cabinet) mit 120kg Belastung zu testen.

Beachte bitte auch die Distanz der Schrauben, man darf nicht zu nah oder zu weit setzen. Ich habe das hier auf Deutsch gefunden:

https://www.huettemann.de/lagerkatalog/download/osb4_belastung.pdf

Ich wuerde immer mit einem margin zur Sicherheit rechnen, vielleicht 20%. Eine Schraube haelt dann also 0.8x70kg = 56kg. Wenn du die Distanzen beachtest und dir das Gewicht deines Schrankes ausrechnest und auf entsprechend viele Schrauben verteilst, solltest du safe sein.

Ich gehe natuerlich davon aus, das die Installationsebene von Wolf Haus fachgerecht konstruiert wurde.

Aw come on! I want to learn! I just don’t want to learn German first.

Edit: D’oh! I had missed the context. All good.

Yeah, but they made the thread and mentioned not speaking English well enough and they were really getting confused and anxious by a bunch of us claiming the only way to turn this situation around is to demolish the building - at that point, some helpful reassurance was in order.

The gist of what I said was: the wall is fine, the manufacturer assures a point load of 70kg for the installation layer (so basically 70kg per screw), looking at some local regulations will give you an idea of how heavy a kitchen wall cabinet can get (going at it from this angle is helpful in case you need to discuss liabilities at some point), distribute that load over screws mounted at proper distances, add a safety margin and you should be good.

Whoops! I had missed that part about struggling with English. You’re a good person. Thanks!

Super danke !!! : )

Noch etwas: die beste Methode ist wirklich, sich mit Bleistift vor der Montage der Gipskartonplatten die Lage der Hoelzer zu markieren.

Falls du das an einer Stelle vergessen hast, kannst du spaeter immer noch einen stud finder verwenden. Ich kenne die amerikanischen brands, habe aber mittlerweile auch solche Geraete gebraucht und getestet.

Der gruene stud finder von Bosch ist trash, aber der GSM120 aus der professional Reihe funktioniert gut:

https://www.bosch-professional.com/de/de/products/gms-120-0601081000

Findet auch elektrische Leitung und Rohre

Ja voll cool!

Ich habe alle Wände abfotografiert und Abmessungen der Lattungen (30cm Abstände) gemerkt. Aber das es sowas gibt ist ja echt wahnsinn. Danke!

There’s about one person in this thread that knows what is going on. Ignore pretty much everyone else.

As is tradition

It didnt allow me to post two pictures.

Are those studs not sitting on a plate?

Yeah there is so much crazy shit going on in these pictures I am doubting my own understanding and I was a rough carpenter for several years.

Why are the studs on the flat? Where the hell is that sill plate? No headers over the windows? No cripples under the windows? Is that stud next to the window opening cut at the bottom? Why are the studs spaced so… creatively

I could probably spot a few more but I honestly think I just don’t know what this building is or where it is. Clearly not in US and maybe it’s a shed or something and not a dwelling. Too much I don’t know to talk shit.

Edit: is there like an actual structural wall on the exterior that we cannot see? Maybe all this stuff is just to provide structure for drywall and electric. That would maybe make sense.

From the links he sent, it looks like he’s just building a non-structural insulating wall on the interior which allows for running electrical lines.

Yeah, this isn’t framing per his link. That OSB is the interior of the structural wall and he’s just building out with 6x6 cm (what we’d think of as 2x2 inch) to hang his (likely 1/4" equivalent) drywall and provide electrical service.

https://www.wolfhaus.info/images/DETAILS/wandkonstruktion_oekoline.jpg

I think you’re right. If this picture was taken in the US or Canada, I would be panicked for OP. But honestly I thing it might be something we don’t do here so it looks crazy, but only to us.

You’re right. After moving to Germany, I can tell there is nothing wrong with this picture, but it sure looks crazy out of context.

Interestingly enough, most residential houses I looked at had solid, steel reinforced concrete walls everywhere.

If this picture was taken in the US or Canada, I would be panicked for OP

Same tbh.

Oh, I see. Still not sure I’d hang cabinets from that.

I think it just depends on how he’s attaching it. If it’s going into the top and sill plates behind the OSB, there’s not really much of a chance of it going anywhere.

But those gaps at the base, where the stud should be abutting a sill plate…what will the drywall be attached to?

What does this mean? Am I doing something wrong?

No, I was actually translating it for the American construction folks. What you’re doing is actually how we cover up plaster walls on remodels. It’s just not something I’ve ever dealt with when I was a construction supply salesperson.

I thought they were flat too, but he said they’re square. I’m very confused.

I worry they’re just attaching things to the cladding.

I can give you the wall structure here:

Maybe you can help me with this information

What do you mean? Sorry I am not english speaking.

I can give you the wall structure here:

Maybe you can help me with this information

The wall is behind the 6x6 cm squared timber.

The reason for 6x6 cm squared timber is for the electricity level.

This is translated, I don’t speak German.

Unter diesen 6 x 6 cm großen Stollen befindet sich kein Stück Holz. Es sieht so aus, als hätten sie keine nennenswerte strukturelle Unterstützung.

Holy shit, is that load bearing plywood on the far wall (with the rectangle window).

My friend, you need help from someone that knows what they are doing and familiar with local codes before proceeding any further.

That wall isn’t structural. There’s a much thicker wall behind it; this is just a thin internal layer for running electric and mounting drywall.

https://i.imgur.com/AbsJjCh.jpeg

My concern is that those big beams (blue) end where they meet the plywood (yellow). Which means they are transferring their downward force into the board(s) highlighted in green. That in turn presses down on the vertical studs highlighted in red. These aren’t connected to anything on the bottom. So the weight from the beams gets supported by the screws attaching all these pieces to the plywood wall? Maybe if they’re just for looks and not structural support. Maybe that’s how it’s done in germany.

Behind the green board, behind the OSB, there is a very thick top plate that those beams are sitting on and based on what the OP said to me, that is then framed down to a sill plate also behind the OSB. Nothing on the outside of the OSB is structural and he’s actually screwing those 6x6 cm boards into what’s behind the OSB. They’re using the OSB as a vapor barrier instead of faced insulation like we do and also protecting the studs with that vapor barrier from the interior of the house.

Edit: Truth is, what’s funny about OP’s wall and the response it’s getting is that it’s better constructed than most American buildings you could find. We don’t tend to put as big a gap between the vapor barrier and the interior heated space and we don’t tend to include the studs as protected by that vapor barrier. When we do we use plastic sheeting, not OSB, because that’s too expensive. I’d imagine the R value on his insulation is also much higher than ours.

They are not American, Germans build way different so how they do things does not make sense without understanding what is going on.

Not just germans, aussie here, assumed that was internal walls (which differ from external). Seen a few double brick/ concrete framed out like that

Mind you our building standards have gone down the shitter since the 90’s…

I think people don’ know that the “studs” what I didn’t know were are hidden behind the Plywood.

Yeah, folks are having a hard time wrapping their head around how it structurally works but it obviously does since they’re building housing developments with it. The picture just shows the sill plate and top plate (the two thick pieces of wood on the top and bottom of the wall behind the OSB[what we call the plywood on the inside]) with insulation sandwiched between, but there has to be lengths of wood going from those to hold them together (which we call studs). They’re mistakenly thinking that your 6x6 cm pieces of wood are those studs.

So I guess I should be fine?

I am having heart attack and panic right now.

My construction dude told me to apply 6x6 cm squared timber for installation (electricity) and spread the about 30 cm apart from each other around the house. Once the electrician comes and installs everything and is finished I can install plasterboard onto the 6x6cm squared timber.

I am just not sure if I can hang anything on the plasterboard that is attached to 6x6cm timber. It would be alot more stable if I could get rid of the 6x6cm timber and attach plasterboard to plywood (like the inside walls).

At the end he said it’s for electricity only and my safety so I don’t break the vapor barrier later if I screw something into the plasterboard. So I have about 6 cm “air” before the “real” wall starts after the plywood.

Its basically from inside to outside:

Plasterboard -> 6x6 cm squared timber -> Plywood -> Studs -> Vapor Barrier -> Insulation (240mm wool) ->… in the end the totall wall is about 39cm thick.

So are the 6x6s attaching just into the plywood or are they going into something behind the plywood? Overall it sounds fine what he told you to do, but what they’re attaching to and how you do what we call “blocking” to secure them is how you determine if you can hang cabinets.

Edit: Per your additional information, what you’re doing is fine but I’d ask him specifically about where you want to hang cabinets because you’d need to make more consideration. They put a lot more strain than thin drywall to the fasteners that are holding them up.

All of the OSB is the inside of the already constructed wall. It’s interior fascia, essentially, with insulation behind it.

deleted by creator

Here is a picture of the wall how it looked when the house got delivered

The responses are hilarious. Be brave OP

deleted by creator

We use three horizontal strips of thin flat stock metal attached to the studs with truss head screws before sheetrock to provide solid blocking at top and bottom of upper cabinets and also at top of base cabinets. The stock can be 20 or 22 ga. And 6" wide. You still may want to catch studs as best you can. I posted a picture showing the two strips that hold the upper cabinets. I’m not sure what the metric equivalent to gauge would be but you guys probably have something similar.

How are you getting any insulation in a wall that thin?

Insulation is already behind the squared timber.

The wall is actually behind the frame I am putting on the wall. It is an installation level for electricity and I can hang my plasterboards on that.

The insulation is 240mm thick behind the Plywood. That is where the vapor barrier is and the other plywood.

https://www.wolf-haus.de/ihr-mehrwert/mehr-holz/

If you scroll down:

The wall is complete. I am doing step 5 (6x6 cm timber) and tthe plasterboard. Behind the timber that I am putting on the wall is about 33 cm thick

Looking at the pictures, I think you should stop immediately and hire a professional.

I didn’t do much yet.

I only attached a few 6x6 cm squared timber onto the main wall that is 33cm thick currently. But I will ask my construction dude.

deleted by creator

I would not. 6cm is about 2 1/2 inches and I would not rely on a wall framed any less thick than 4-by (3.5 inches). Thinner means more flexion which will lead to problems of your plaster cracking and cabinet flushness issues. In terms of strength, it’s probably okay, assuming you have fastened that framing solidly.

The trick to finding your studs is to pre-mark your plaster board and keep transferring those marks outward up to the point of hanging your cabinets.

Hi thanks!

Can I just install more 6x6 cm frames and make it more stable in the area I want to hang something or would that not help?

In general, I can hang plasterboard on 6x6 though right?

No. Beam deflection goes as the inverse 4th power of beam thickness in the direction of bending. Adding more material lateral to the direction of bending does not help.

Yes, you can certainly hang plasterboard on that.

My english isn’t that good I think I can’t follow.

The beam in that room is holding a top floor and roof and should hold way more. The wall that the beam is sitting on is about 35 cm thick.

Der Poster ueber dir sprach allgemein uber dir Berechnung der Durchbiegung von Balken, hier die 60x60mm Kanthoelzer.

Er meint damit also, dass es nichts bringt, weitere Lattungen anzubringen?

Mein Plan ist aktuell:

Küchenanbieter anschreiben und Monteur der Küche ob die Lattungen so in Ordnung sind. Die angebrachte Lattung markieren, sodass der Monteur später dann die Hängeschränke an den Rigips & Lattung schrauben kann und nicht ins “leere” trifft.

This looks like a disaster waiting to happen

Why you say so?

Unless I’m missing something I just don’t see how those studs are providing any real support to the wall.

Empty cabinets are heavy. I’d be worried about those studs giving way.

Hard to tell tho just looking at this picture.

Those arent studs.

The Studs are in the wall behind the Plywood.

That is just 6x6 cm for electricity and safety space not to danage vapor barrier behind the real wall

Then I recommend posting some additional pictures otherwise you’ll never get the insight you’re looking for

Are you getting this work inspected by anyone?

That work, while precise, would not meet code where I live.

Yes.

I have two specialists for wood houses coming.

The wall behind the 6x6cm timber that I put on is about 40cm thick. I am basically just adding 6x6cm timber for installation (electricity mainly) and to hang my plasterboards. The windows are sitting on a very thick wood inside the main wall behind the 6x6 cm installation floor

My advice? Knock that “wall” down and pay a proper carpenter to build a proper one. Your studs are too small, they don’t go all the way down, you have no room for insulation, and if you try to hang cabinets on that thing, you’re going to kill someone when the whole sumbitch collapses.My bad, I didn’t know what I was looking at. See OP’s diagram to learn more about this, and ignore my ignorance.

I cant knock that wall down. Its like 40 cm thick.

https://www.wolf-haus.de/ihr-mehrwert/mehr-holz/

Maybe if you see this you can help me :(

So I am attaching 6x6 cm squared timber onto an existing wall that is 40 cm thick

That link is extremely helpful. It seems like you’re fine to attach cabinets to the wall after drywall. The osb is tied into some serious wood framing behind it, and as long as you’re using fasteners that reach into the osb, it should be about as solid as you could want.

The kitchen metal grumpydaddy suggested isn’t expressly needed here, but that’s the most I’d consider doing to it.

Oh, I see. My apologies, I misunderstood what we were looking at. I thought the framing we see was the entire wall, but it’s just non-structural framing on the interior behind the plasterboard to allow space for wiring.

I am not familiar with this style of construction, so I won’t guess at best practices for hanging cabinets on it. But I would imagine that as long as the wall we see is sufficiently secured to the structural wall behind it, you should be able to hang cabinets. To be safe, you could anchor into the wall, but I don’t know enough to say how to do that without interfering with insulation or vapor barriers.

It’s just a subwall that’s adding a thermal break. Presumably it’s anchored to the existing wall.

Please have a look at the images he posted, the wall is absolutely fine. The images he posted are just the inner installation layer, the structural wall and insulation are behind that.